Bending machines

You can count on 247TailorSteel for specialized bending work, often in smaller series, but certainly also for large production quantities. For that first option, you put the LVD ToolCell bending machines to work, and for the second option (the larger volumes) we have PPEB bending machines available to you.

The bending machine is a press with an upper die and a lower die. The sheet to be bent is placed between the upper and lower dies. The upper die presses the sheet against the lower die, causing the sheet to deform. When the upper die has been fully lowered and the sheet has been deformed correctly, the upper die is raised again and put back in the starting position. The lower die always stays in the same position. Depending on the desired processing, different dies can be used.

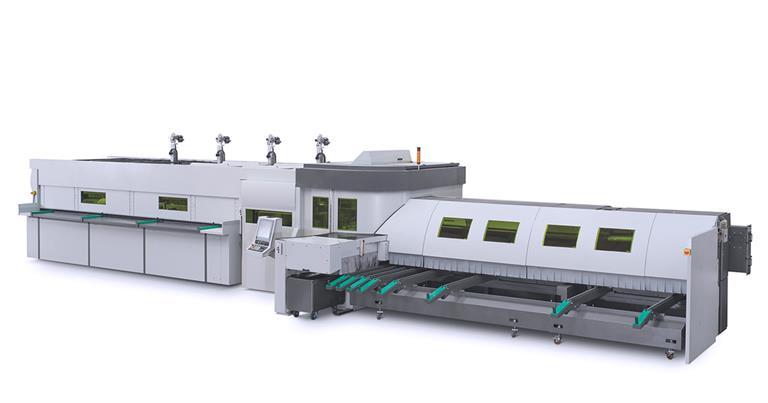

LVD ToolCell bending machines

At 247TailorSteel we currently have 12 LVD ToolCell bending machines in use. The ToolCell makes folding easier and more cost-effective thanks to its thorough automation. This bending press has a shorter setup time and works quickly and in an extremely reliable manner. The automatic tool changer has a warehouse with a series of upper and lower tools.

The bending machines are fully CNC-controlled. The machines have a variable degree angle setting and sheet thickness setting. The automatic tool changer (ATC) minimizes error margins. All tools are in the machine and are automatically switched according to the task. This significantly reduces changeover time and increases fold productivity. Easy-Form® Laser, the LVD patented system for monitoring and correcting angles during the pleating process, ensures that even the first piece is perfect. In other words: first time right, zero defects. The benefits, once again:

- Accurate positioning

- Spring-back correction

- Fast loading and unloading of tools

LVD PPEB bending machines

These bending machines offer efficiency and speed without sacrificing the quality you expect from 247TailorSteel. They are ideal for processing less complex pleats applied to large production volumes. And these bending machines, too, operate 24 hours a day, 7 days a week for you.

* Locations Varsseveld, Oyten and Hilden

Type of ATC's: LVD ToolCell 220/4000 en 135/3050

Type of PPEB's: LVD PPEB 80/1500 en 80/2000

Maximale pressure force of ATC's: 220 ton

Maximale pressure force of PPEB's: 80 ton