What is CO₂ laser cutting?

CO₂ laser cutting is a sheet metal processing technique that uses an electrically driven gas laser. The laser cuts contours into metal sheet material such as steel, stainless steel or aluminium. CO₂ cutting technology is highly accurate and offers a lot of shaping freedom. This even makes it easy to cut complex shapes. CO₂ laser cutting technology has been on the market since the 1970s.

CO₂ laser cutting with oxygen or nitrogen?

In CO₂ laser cutting, laser cutting is possible with both oxygen or nitrogen. The difference is that oxygen burns the material and nitrogen melts the material. Thicker materials can be laser cut when using oxygen. The disadvantage of cutting with oxygen is that an oxide layer forms on the cutting surface. This can break off, which is not desirable if the products are preserved without pre-treatment (blasting). Nitrogen laser cutting creates a clean cutting surface without oxide film. On the other hand, when cutting with nitrogen, cutting surfaces are sometimes less smooth and slight burring may occur. The amount of spatter on the inside of the product is also greater than when cutting with oxygen.

CO₂ laser cutting at 247TailorSteel

TRUMPF CO₂ laser cutting machines

247TailorSteel laser cutting machines are from the brand TRUMPF. Two of the 39 laser cutting machines are CO₂ laser cutting machines. However, most of our machinery consists of fibre laser cutting machines.

CO₂ versus fibre

The wavelength of a fibre laser is smaller than that of a CO₂ laser (1 micrometre versus 10 micrometres). The wavelength of a fibre laser is in the infrared range and is therefore more applicable to highly reflective material such as stainless steel. The material to be cut absorbs a smaller wavelength better than a larger wavelength.

The amount of fibre laser cutting has increased significantly at the expense of CO₂ laser cutting. This increase in popularity, in the Netherlands anyway, can be explained by the fact that thin sheet metal is processed in large quantities in the Netherlands. A fibre laser cutting machine is ideally suited for this purpose thanks to its higher cutting speeds and lower energy consumption compared to CO₂ laser cutting technology.

Which technique gives the best results?

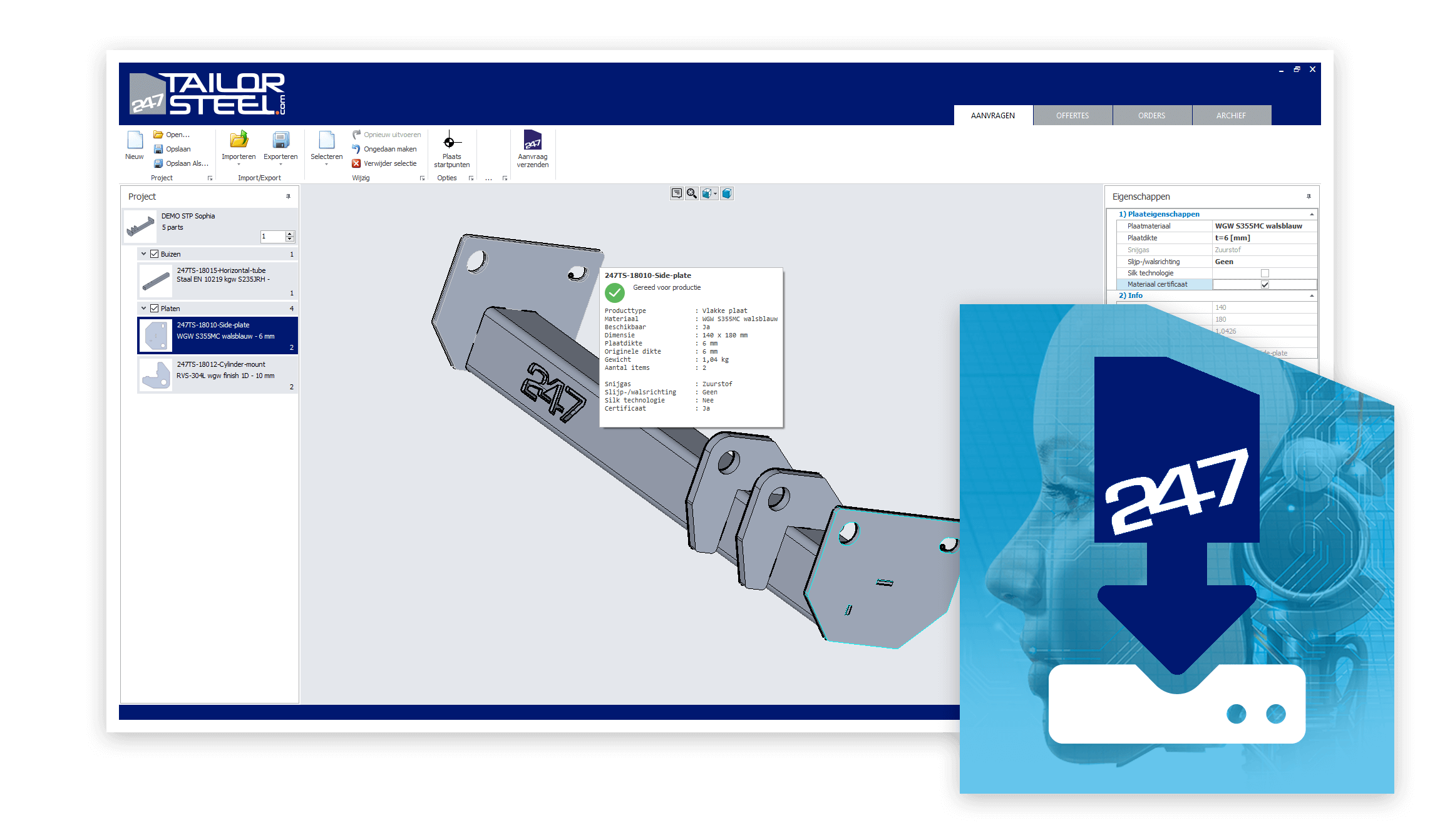

Which technique (and therefore which machine) is suitable for your specific laser cutting task? To answer this question, we would like to introduce Sophia®, our online assistant that uses with artificial intelligence to control production and logistics, enabling the production of laser-cut metal plates and tubes in no time at all. All this without any human support. Sophia® is at your service 24 hours a day, 7 days a week.